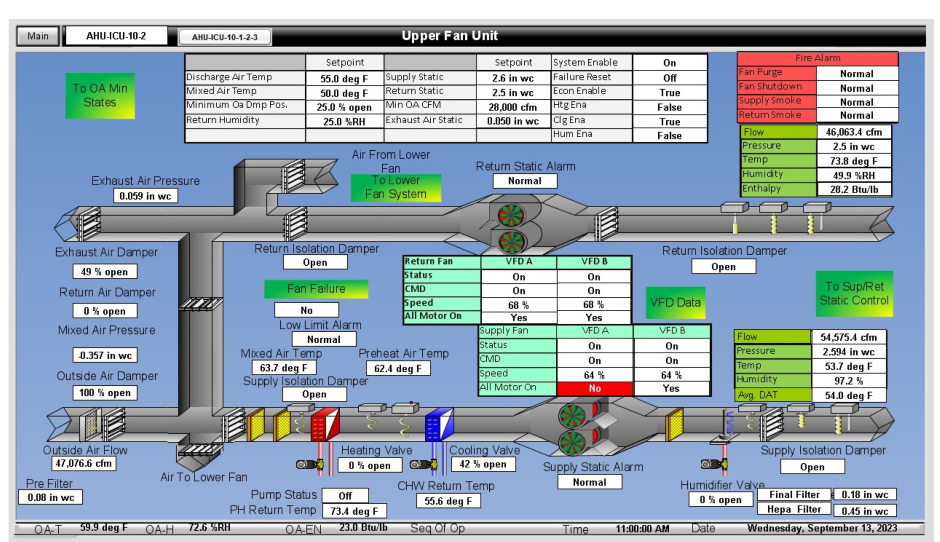

Exploring Integration Opportunities with Airflow Measurement Stations

Thermal dispersion airflow measurement stations with BACnet communication protocols address the industry's need for data integration and operational transparency. Advanced BAS systems use extracted data for decision-making, trend analysis, interoperability, and issue resolution. The advantage of using a BACnet airflow sensor is that it allows for more actionable data with the option of using analog for the local controller.